-

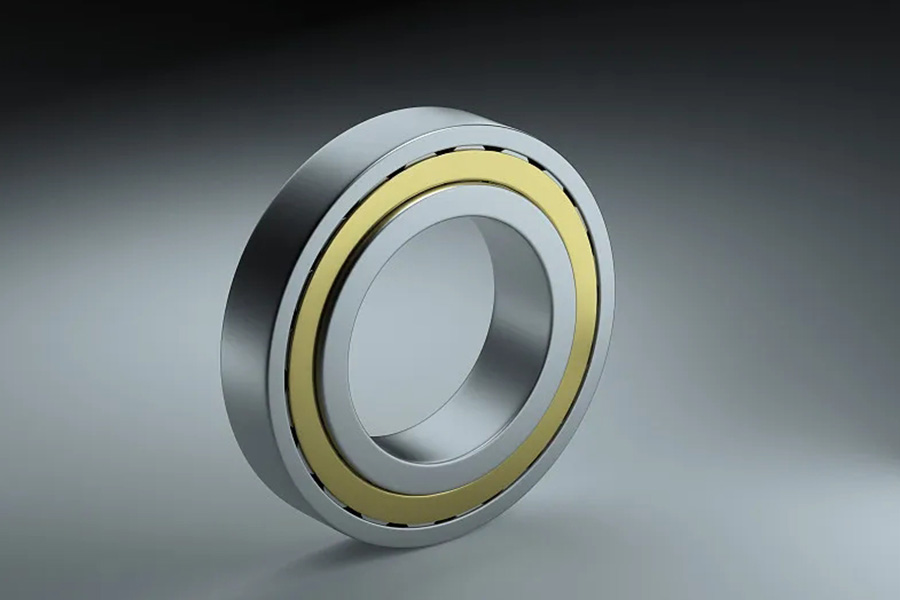

Causes of Noise Generation at Maximum Rotational Speed in Rolling Bearings

2026-01-12

The causes of noise in deep groove ball bearings are complex. One factor is wear on the mating surfaces of the inner and outer rings. This wear disrupts the alignment between the bearing and housing, or between the rolling elements and shaft, causing axial displacement.

-

Purpose of Bearing Preload and Methods of Bearing Preload Direction

2026-01-12

Bearing preload refers to the process of generating an initial pressure and pre-deformation between the rolling elements and the inner/outer rings during bearing installation. This ensures both rings remain in a compressed state, enabling the bearing to operate under negative clearance when subjected to working loads.

-

Maintaining Rolling Bearings: A Comprehensive Guide to Ensuring Efficient Operation

2026-01-12

Maintaining optimal performance and extending the service life of rolling bearings hinges on a regular and appropriate maintenance strategy. This article aims to guide you in effectively caring for these vital mechanical components to ensure smooth equipment operation.

-

The Effect of Preload and Rotational Speed on Bearing Stiffness and Temperature

2026-01-12

Bearings serve as vital components in mechanical rotary systems, with their stiffness and temperature directly impacting operational efficiency. To enhance rotational precision, increase assembly rigidity, and minimise shaft vibration during machine operation, preloaded rolling bearings are frequently employed—such as those in machine tool spindles.