-

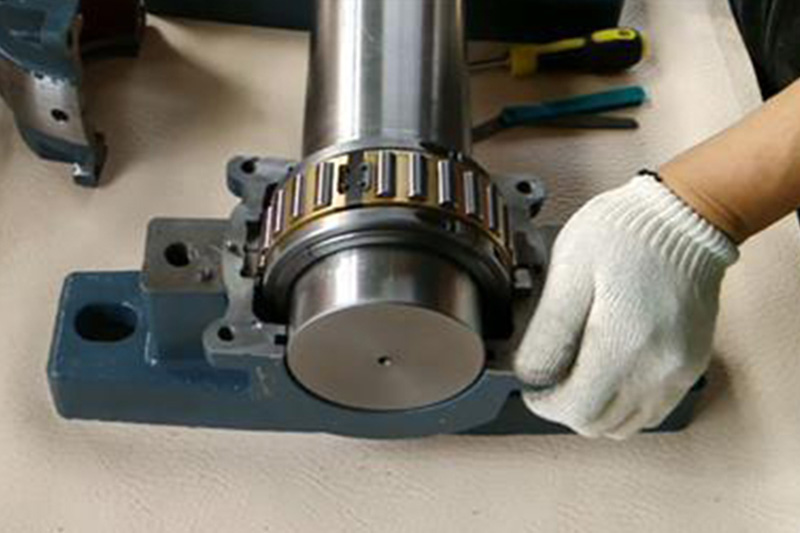

What factors affect bearing service life?

2026-01-12

Whether in terms of installation or operational maintenance, numerous external factors can impact the service life of rolling bearings, such as improper installation or inadequate maintenance. Let us share the common factors that influence bearing longevity.

-

Characteristics and Causes of Cracks in Bearing Grinding

2026-01-12

Grinding is a common method of metal cutting in the mechanical manufacturing industry and is also widely applied in the bearing manufacturing sector. Bearing components that have undergone heat treatment and quenching may develop a network of cracks or finely arranged, regular fissures during the grinding process, termed grinding cracks. These not only affect the appearance of the bearing components but, more critically, directly impact their quality.

-

Common Factors Contributing to Magnetic Trace Defects in Bearing Outer Ring Cross-Sections

2026-01-12

Defects are relatively prone to occur during metal hot working processes. For instance, in forging operations, cavities and microcracks generated by forging overheating may readily become fatigue sources leading to contact fatigue failure in bearings.

-

Analysis of Bearing Damage Conditions and Causes with Countermeasures

2026-01-12

Damage condition: When the bearing rotates under load, the raceway surfaces or rolling element surfaces of the inner and outer rings exhibit fish-scale-like spalling due to rolling fatigue. Causes: Excessive load. Improper installation (misalignment). Torque loading. Foreign object ingress, water ingress. Inadequate lubrication